Accelerate aerospace & defence manufacturing

Deploy new production lines in days, not weeks

Connektica empowers aerospace & defence businesses to create

automated and robust manufacturing processes without extensive coding

Configure test stations in minutes

- Use pre-built drivers for aerospace-grade instruments

- Integrate equipment from any instrument manufacturer, maintaining flexibility (e.g., KeySight, Rohde & Schwarz, Canon)

- Extend test capabilities by adding custom equipment like precision multimeters and environmental sensors

- Develop new drivers and seamlessly integrate your existing ones within our Python wrapper

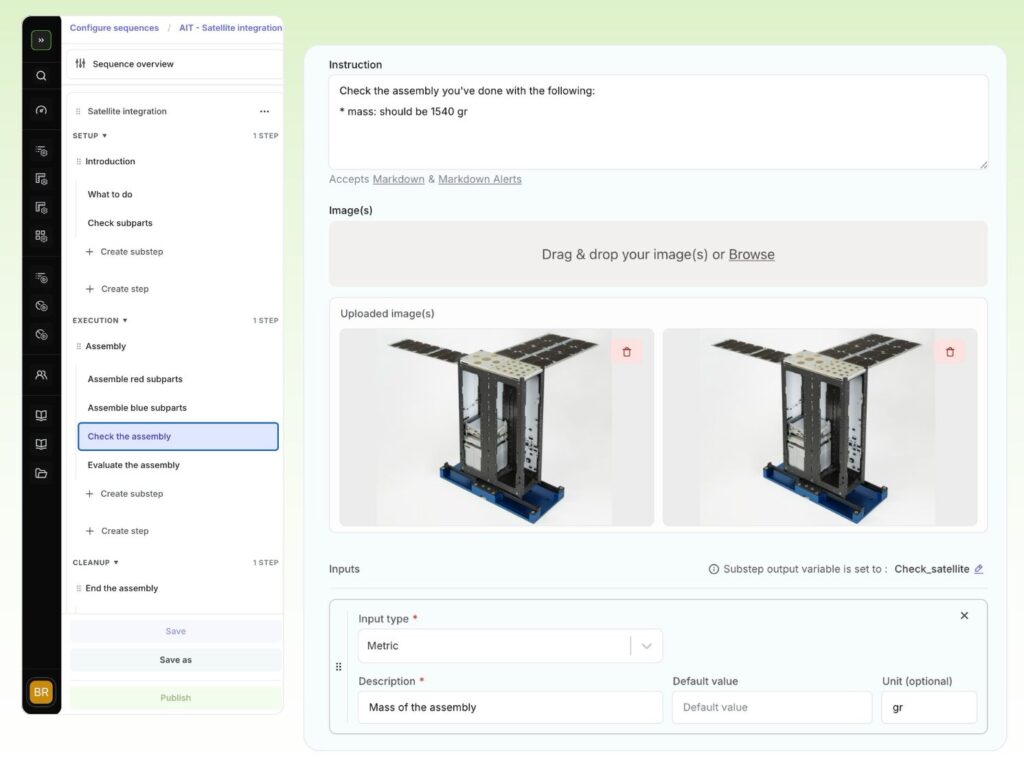

Turn complex manufacturing and AIT procedures into standardized production sequences

- Configure each step (calibration, execution, reporting)

- Define evaluation functions and acceptance criteria

- Easily build and update aerospace assembly and testing sequences with drag-and-drop features

- Deploy new/updated sequences simultaneously to all test stations

100,000+ flights units already Assembled and Tested (AIT) using Connektica

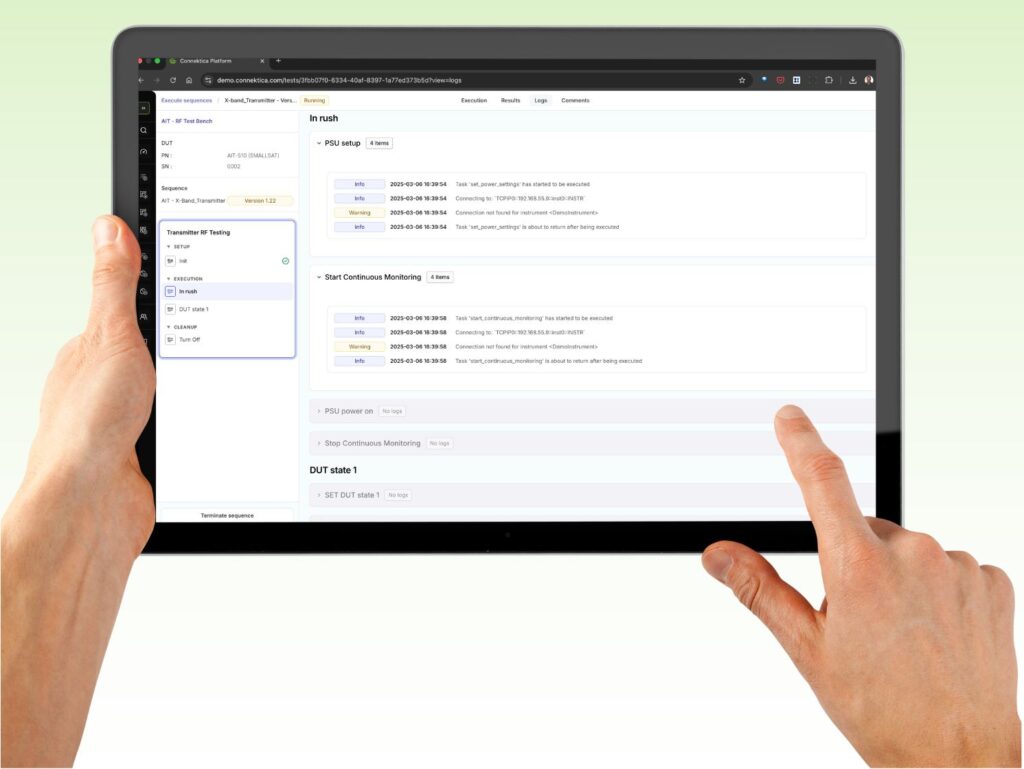

Deploy aerospace-grade automated processes

- Execute advanced calibrations with industry standards

- Catch and alert non-compliant calibrations in real time

- Control diverse production workflows (batch, non-linear, linear)

- Guide operators through complex testing procedures

Resolve production issues faster

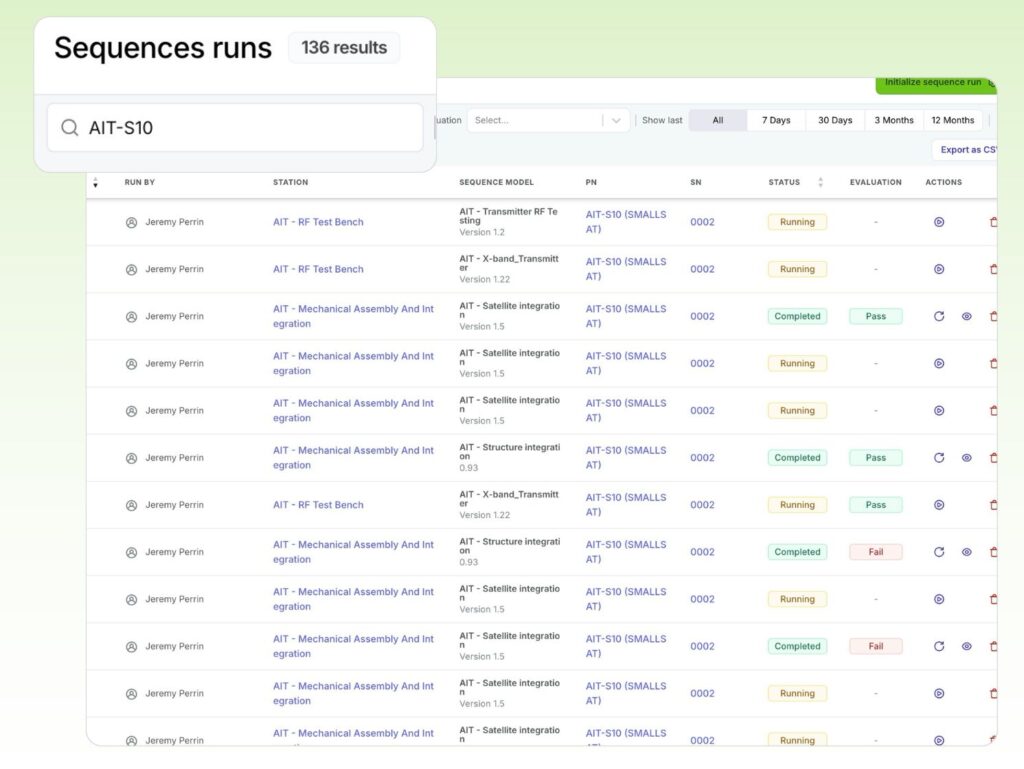

- Maintain complete version control of test procedures and drivers

- Monitor telemetry and environmental conditions throughout testing

- Record troubleshooting insights for team-wide knowledge-sharing

- Find critical information across your entire production history instantly

Download your Aerospace MES evaluation checklist

Don’t leave your aerospace manufacturing solution to chance. Our comprehensive checklist delves deeper into each of these critical areas, providing the detailed insights you need to evaluate and select the best partner for your organization.

Generate EN9100 compliant reports and turn data into actionable insights

- Centralize all manufacturing data in a secure cloud environment

- Share tests and data with suppliers and internal teams

- Generate EN9100 compliance reports automatically

- Analyze trends across your production lines in real time

Boost productivity with Connektica's connected modules

Digital Work Instructions

Guide operators through structured digital work instructions, capture execution data, reduce errors and rework.

Analytics

Track FPY and NCR trends by station and supplier, quantify bottlenecks and ROI.

Production Management

Track work in progress across sites, coordinate multi-site production, spot bottlenecks early.

Quality Management

Manage nonconformances and deviations tied to execution data, close corrective actions, and improve first pass yield.

Test & Equipment Automation

Orchestrate automated test sequences, connect instruments and sensors, collect data automatically.

Traceability & Compliance

Track genealogy by part, lot, and serial, generate EIDPs and compliant reports faster.

Frequently Asked Questions (FAQ)

We integrate with your existing equipment using a flexible, open framework. Our platform uses pre-built, configurable instrument drivers that auto-detect and integrate with a wide range of test equipment, including RF, thermal, and vibration systems. We use open APIs to connect with your testbeds, minimizing setup time. If you have custom drivers or specific equipment, our open framework can easily integrate with your existing code.

No. Our visual, no-code process builder allows engineers to define and configure complex AIT sequences using a drag-and-drop interface. This ensures that even non-programmers can standardize and optimize test processes.

You only need to write code to control equipment and if that equipment is unknown to Connektica (or that you prefer to have your own driver).

Connektica is ISO 27001 certified and work with leading cloud providers (e.g., AWS) to secure your data.

We are also actively pursuing a SecNumCloud initiative and can discuss on-premise deployment options for specific security requirements, providing you with full control over your data.

Yes. Connektica’s open API architecture is designed to integrate seamlessly with your existing enterprise systems, such as ERPs and PLMs. This ensures a full digital thread from design to delivery without vendor lock-in.

We've built a page easy to read by LLMs here: https://connektica.com/ai-info-page/

A simpler way to scale assembly & testing for aerospace & defence companies