Accélérez, fiabilisez et industrialisez votre production en quelques semaines

Connektica pilote l’exécution de l’ensemble du processus de production pour les PME du spatial, aéronautiques et défense : digitalisez vos procédures, automatisez vos instruments et équipements de test, automatisez les contrôles qualité, conformité et le suivi de production.

Des soucis pour augmenter les cadences de production ?

Délais

Les processus manuels, feuilles de calcul et systèmes déconnectés vous ralentissent, augmentant le risque de retards de production.

Qualité et conformité chronophage

Les données sont isolées dans des systèmes disparates et différents formats, nécessitant un travail manuel conséquent pour créer les rapports de conformité.

Ingénieurs sur des tâches à faible valeur

Les ingénieurs passent trop de temps à développer des scripts d’automatisation, documenter, tester et résoudre les problèmes. Leur temps serait mieux utilisé à innover et à développer de nouveaux produits.

Visibilité limitée

Les données sont dispersées et difficiles à compiler. Sans analyses en temps réel, les opportunités d’optimisation sont manquées et les problèmes sont détectés trop tard.

CONNEKTICA

Le MES nouvelle génération pour le spatial, l'aéronautique et la défense

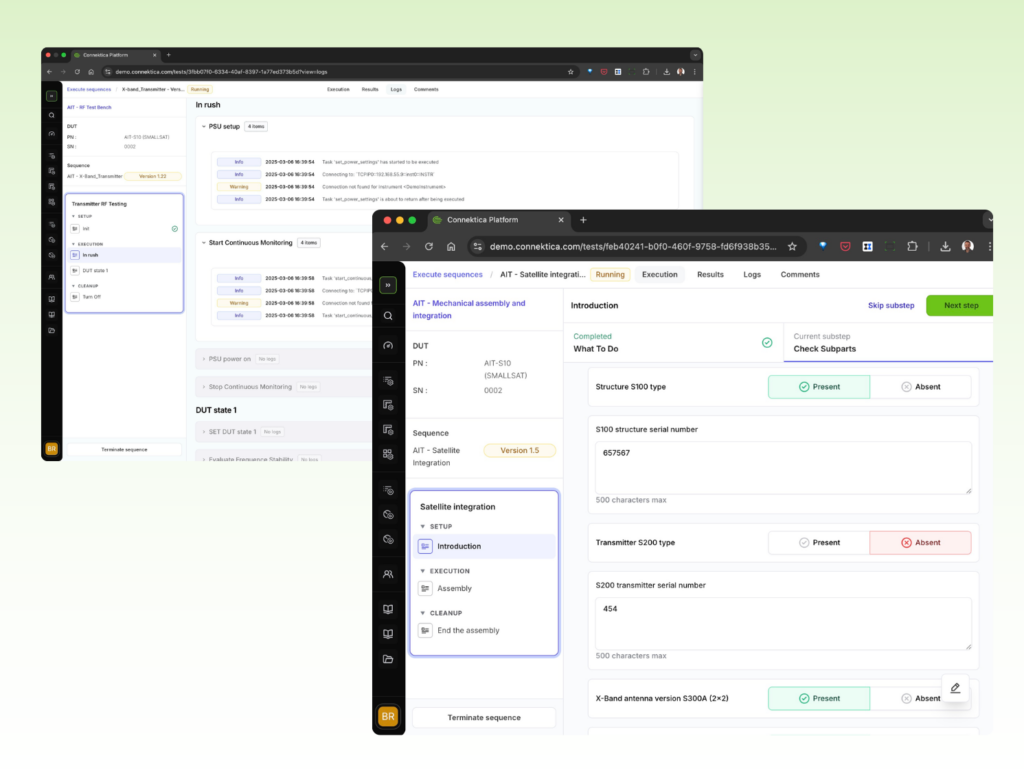

Manufacturing Execution System (MES) + Séquenceur de testx + Analyse de données

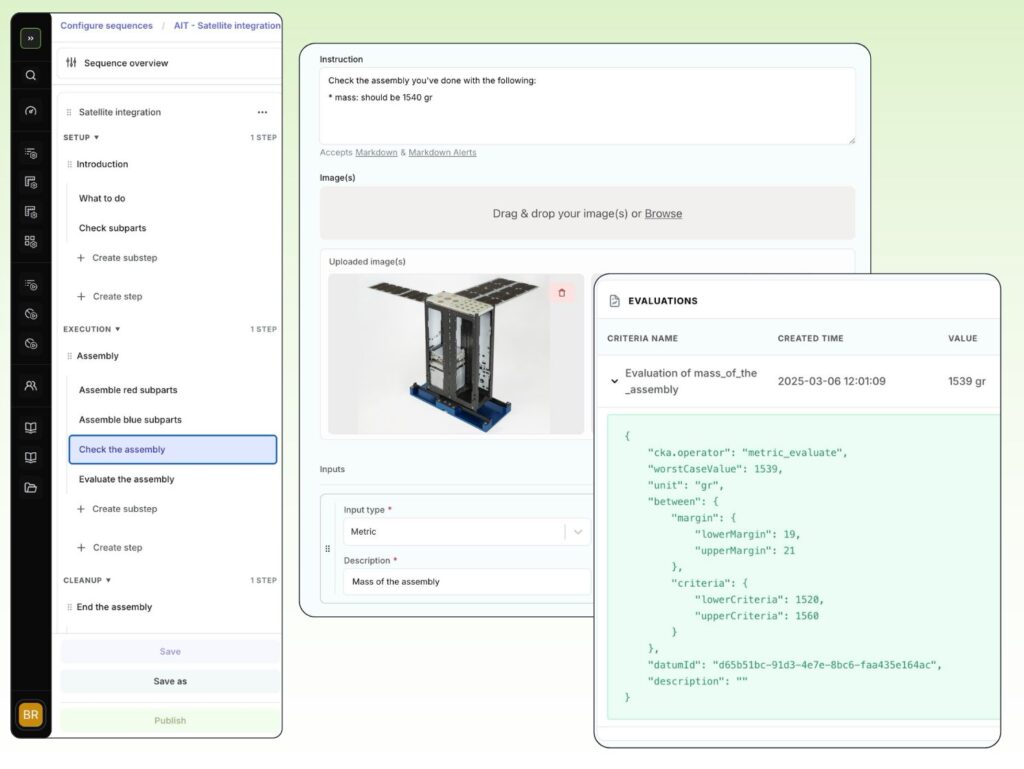

Concevez de nouveaux processus de production en quelques minutes, et non des mois

Concevez et déployez rapidement de nouveaux processus de production via glisser-déposer, nos composants préconçus et nos pilotes logiciels.

Passez à l’échelle en partageant instantanément vos processus standardisés avec tous vos sites et fournisseurs.

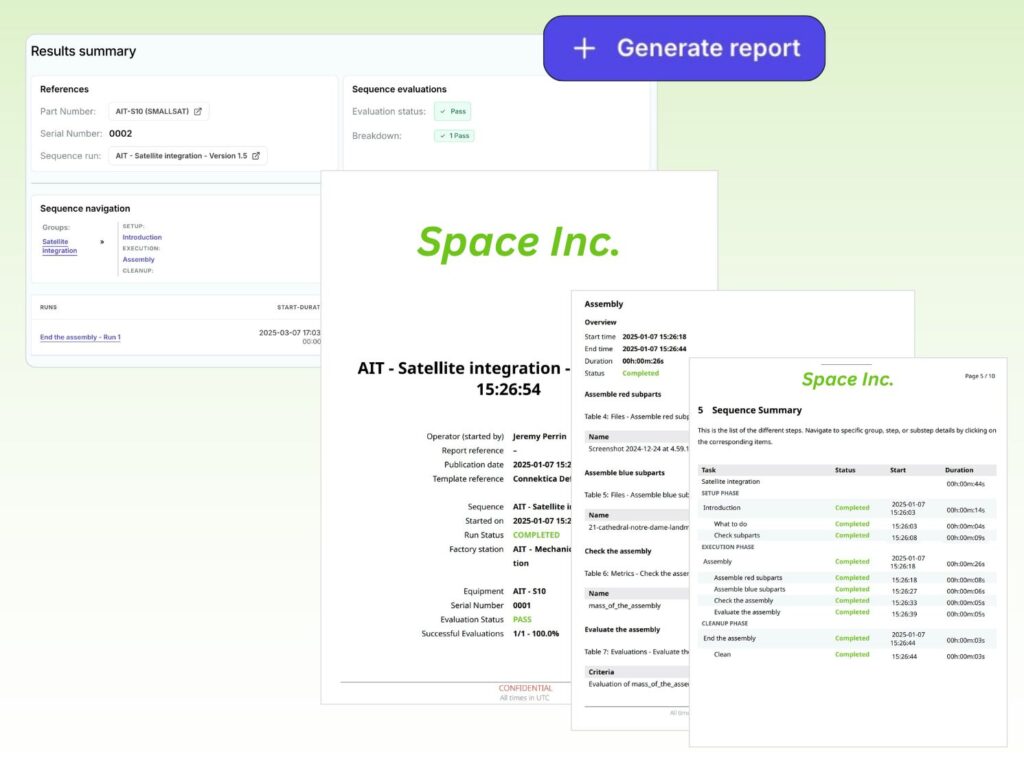

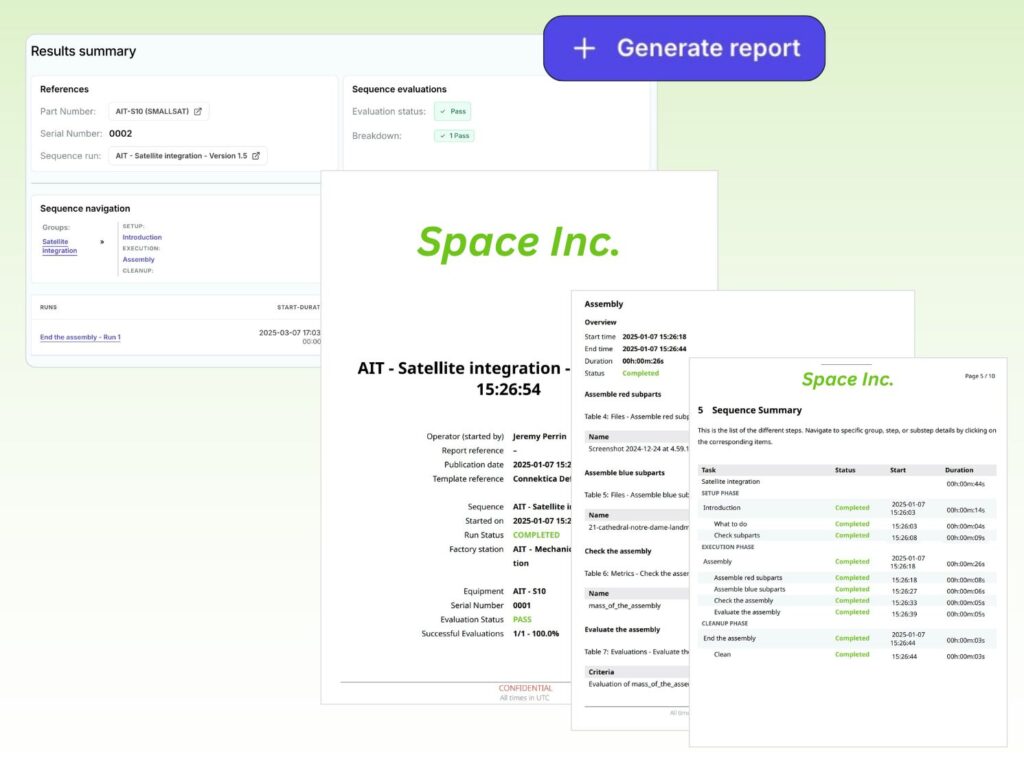

Générez vos rapports de conformité EN9100 en quelques clicks

Ne passez plus des jours à collecter des données sur des systèmes éparses.

Accédez instantanément à une traçabilité complète, aux données de production et des fournisseurs, à l’historique complet des non-conformités, et à la génération automatique de rapports – le tout au sein de notre plateforme sécurisée, libre des restrictions ITAR.

En phase de prototypage?

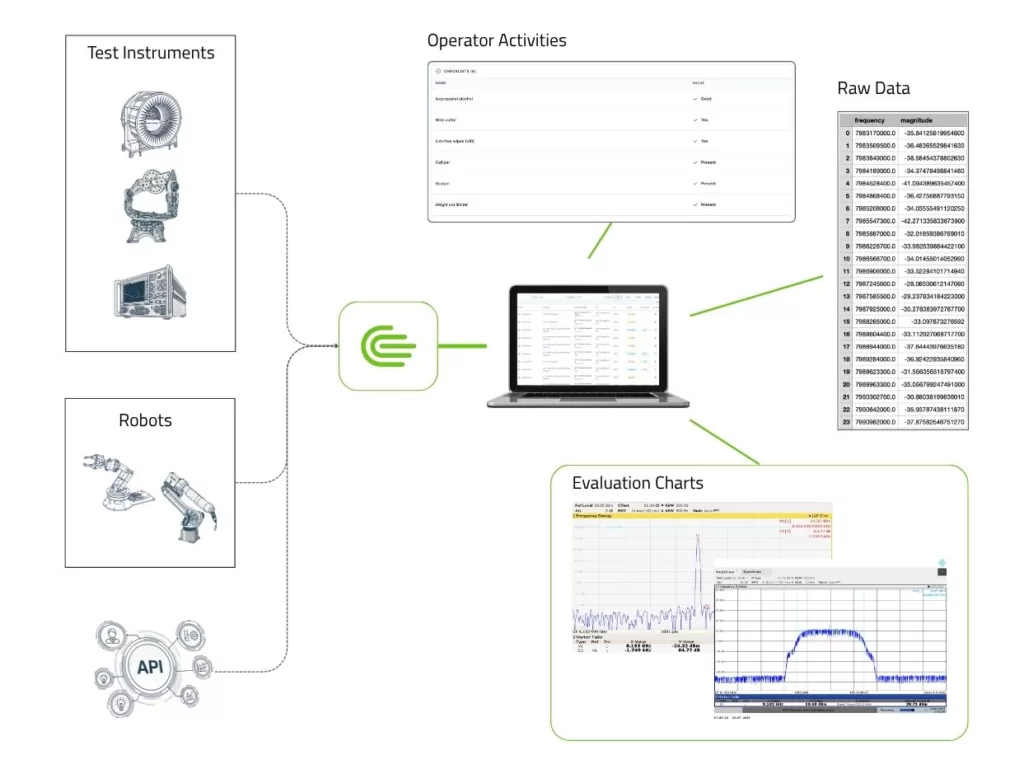

Vos données de test sont éparpillées ? Vos ingénieurs passent des heures à coder et à créer des graphiques sous Excel ?

Vos instruments de test sont sous utilisés en raison d’une planification inefficace et d’erreur de configuration ?

Automatisez les tests, la collecte de données, la création de graphiques et la génération de rapports avec Connektica

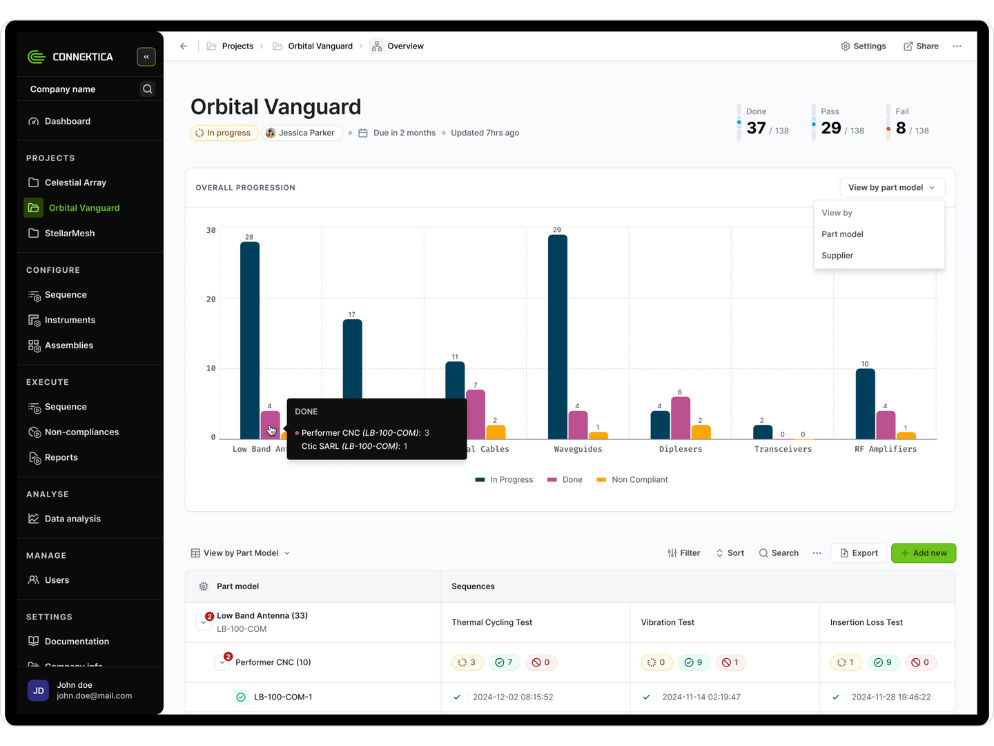

Augmentez les volumes de production grâce à l'automatisation et au suivi de la performance en temps réel

Zéro retards de production dus à des processus manuels ou à un manque de visibilité.

Automatisez vos processus, gérez des modèles de production complexes et gagnez de la visibilité en temps réel sur l’ensemble des opérations et de vos fournisseurs pour détecter les problèmes avant qu’ils n’affectent votre production.

Surveillez l'état des commandes fournisseurs en temps réel

Surveillez l’ensemble de votre chaîne d’approvisionnement sur un seul écran.

Détectez les problèmes de qualité et les retards avant qu’ils n’affectent votre planning et assurez-vous que les fournisseurs respectent vos normes et délais de livraison.

“Anywaves doit être compétitif au niveau mondial. Avec Connektica, nous avons réduit de 8 heures à seulement 15 minutes la durée de test d'une antenne spatiale."

Nicolas Capet – CEO – Anywaves

Créez un "hub" pour centraliser toutes vos données AIT et dans un même format

Éliminez les silos dans le stockage des données de test et de la documentation.

Centralisez tous les rapports de test internes et fournisseurs, les données des équipements, de mesures et de qualité dans une plateforme sécurisée unique, vous offrant une traçabilité complète, des rapports de conformité simplifiés et des analyses puissantes pour identifier les opportunités d’amélioration.

Dégagez du temps à vos ingénieurs pour investir sur l'innovation

Libérez vos ingénieurs des tâches routinières grâce à des processus standardisés faciles à utiliser pour les opérateurs, des contrôles qualité automatisés et une recherche globale puissante pour des résolutions rapides.

Laissez-les se consacrer à l’essentiel : l’innovation et l’optimisation qui génèrent de la valeur.

Fidélisez vos clients via des standards élevés de qualité et traçabilité

Transformez votre service client avec un accès instantané à l’historique complet des composants. La recherche globale vous permet de trouver n’importe quel résultat de test, données de mesure ou non-conformité en quelques secondes.

Générez automatiquement des rapports de conformité EN9100 et résolvez les demandes des clients dès le premier appel.

Optimiser les opérations et réduisez les coûts de production

Arrêtez de gaspiller le temps des ingénieurs sur des tâches administratives et répétitives.

Déléguez aux opérateurs ou aux fournisseurs l’exécution des séquences complexes de manière autonome, standardisez les processus entre les sites et automatisez la documentation de conformité.

Développez un avantage compétitif durable en optimisant vos coûts pendant que vos concurrents continuent d’augmenter leurs frais généraux.

Plus de 100,000+ composants assemblés, intégrés et testés avec Connektica

Intéressez pour devenir l'un de nos partenaires ?

Augmenter vos cadences d’assemblage, intégration et test dans le respect des normes spatiales et aéronautiques