Accelerate, error-proof, and scale Aerospace & Defence manufacturing in weeks

Connektica manages the execution of the entire manufacturing and AIT process for Aerospace & Defence SMBs: standardize work instructions, automate execution & quality controls, one-click compliance, and real-time production tracking.

Struggling to keep up with growing production demands?

Production Delays

Manual processes, spreadsheets, and disconnected systems slow you down increasing the risk of production delays.

Time-Consuming Compliance

Data is scattered across disparate systems and in different formats requiring intensive manual work to create EN9100 compliance reports.

Wasted Engineering Time

Engineers spend too much time developing automation scripts, documenting, testing, and troubleshooting. Their time would be better spent innovating and developing new products.

Limited visibility

Data is scattered and hard to compile. Without real-time insights, optimization opportunities are missed and issues are caught too late.

CONNEKTICA

MES for aerospace & defence SMBs

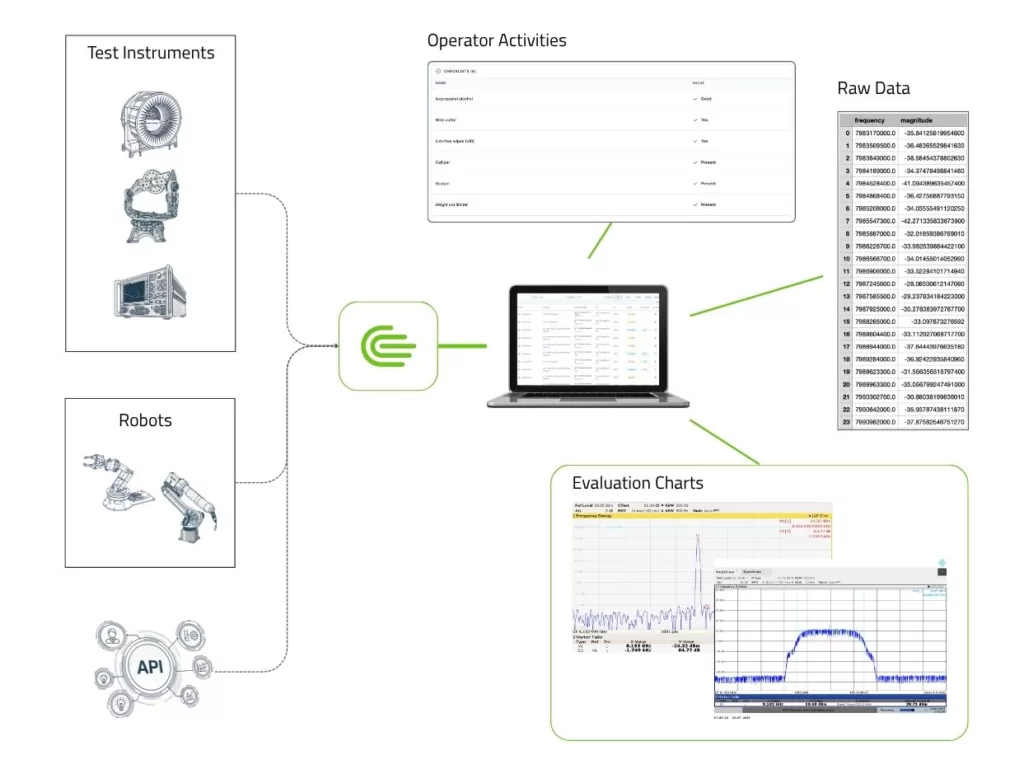

Manufacturing Execution System (MES) + Test Sequencer + Data Analytics

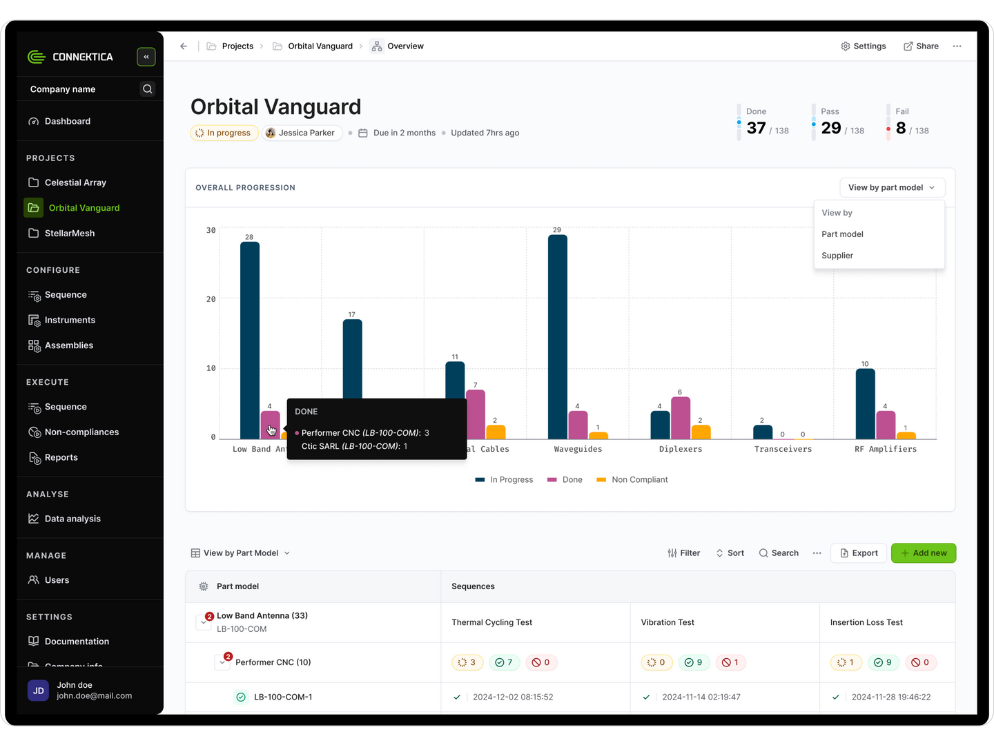

Accelerate manufacturing & AIT with automation and real-time monitoring

No more production delays from manual processes or lack of visibility.

Automate your sequences, handle complex production models, and gain real-time visibility across operations and suppliers to catch issues before they impact production.

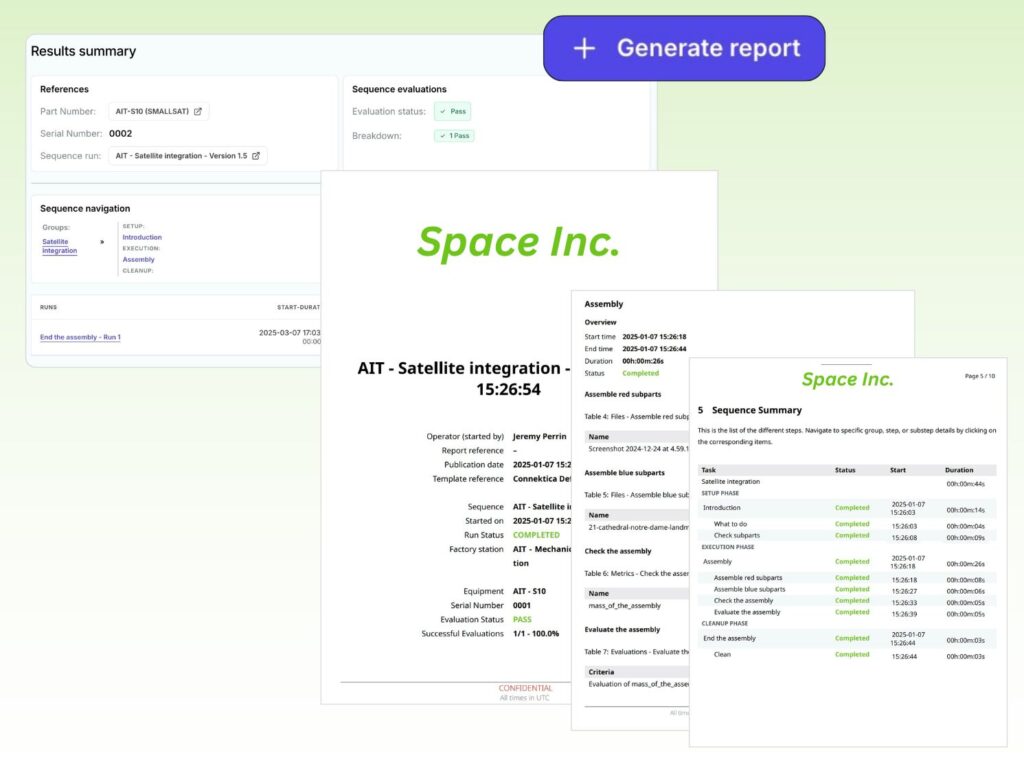

EN9100 compliance reports at your fingertips

Stop spending days collecting data from multiple systems.

Get instant access to complete traceability, production and supplier data, the full history of non-conformities, and automated report generation – all within our secure, ITAR-free platform.

“Anywaves has to be competitive on a global playing field. With Connektica, we have reduced the time to test a space antenna from 8 hours to just 15 minutes."

Nicolas Capet – CEO – Anywaves

Building your 1st prototype?

Struggling with scattered test data? Or Engineers spending hours coding and building Excel charts?

Equipment sitting idle inefficient scheduling and manual setup?

Automate testing, data collection, plotting and report creation with Connektica

Improve manufacturing and AIT efficiency and cut production costs

Stop wasting engineering time on paperwork and repetitive tasks. Enable operators or suppliers to run complex sequences independently, standardize processes across sites, and automate quality documentation. Build a sustainable cost advantage while your competitors keep adding overhead.

Create a unified AIT intelligence hub

Eliminate scattered test data and documentation silos.

Centralize all internal and supplier test reports, measurements, equipment, and quality information in one secure platform, giving you complete traceability, simplified compliance reporting, and powerful analytics to identify improvement opportunities.

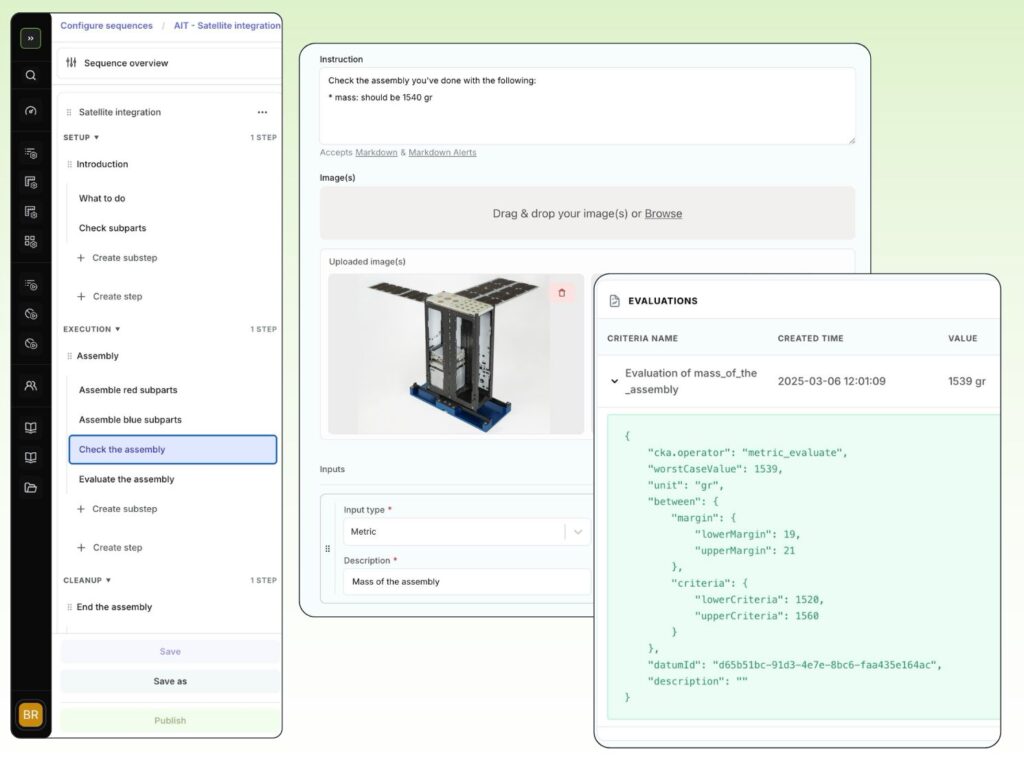

Design new manufacturing & AIT processes in minutes, not months

Design and deploy new manufacturing processes with our drag-and-drop interface, pre-built components, and drivers.

Scale instantly by sharing standardized processes across your manufacturing sites and suppliers.

100,000+ flights units already Assembled and Tested (AIT) using Connektica

Build customer loyalty through unmatched aerospace quality

Transform your customer support with instant access to complete component history. Global search lets you find any test result, measurement, or non-conformity in seconds.

Generate quality reports automatically and resolve customer inquiries during the first call.

Keep engineers focused on innovation

Free your engineers from routine tasks with operator-friendly standardized processes, automated quality checks, and powerful global search for rapid troubleshooting.

Let them focus on what drives value: innovation and optimization.

Monitor supplier order status in real-time

Monitor your entire supply chain on a single screen. Catch quality and delays before they impact your schedule and ensure suppliers meet your standards and delivery windows.

Looking to partner with Connektica?

frequently asked questions

Connektica is purpose-built for the aerospace and defense sector, with a specific focus on small to medium-sized manufacturers. We are designed for companies from prototyping to large series production. Our solution is used by manufacturers of satellites, drones, missiles, aircraft OEMs, and their tier suppliers.

Connektica is a SaaS MES purpose-built for the aerospace and defence companies.

It is a digital solution to manage & automate the entire assembly, integration, and test process, including quality controls and EN9100 (AS9100) compliance.

Unlike fragmented legacy systems, Connektica's complete coverage cuts production cycles by 80% and reduces operator dependence so that they can scale more aggressively.

Key modules include: Automation (e.g., tests, robots), Digital Work Instructions, Data Analytics, Quality Management, Traceability & Compliance, Supplier Management.

Within 2 weeks, your first sequence should be live and save 10-20% of time to your operators. As you build more complex sequences and automate, additional benefits in speed, time saved, and traceability will become noticeable.

Connektica distinguishes itself by unifying core MES features with native test automation, allowing it to directly control test benches and equipment—a capability most traditional MES systems lack. Additionally, it is specifically designed for high-complexity, regulated industries (like Aerospace & Defense), offering out-of-the-box compliance (AS9100, 1-click EIDPs) and rapid deployment for SMBs.

Connektica enforces EN9100 compliance directly on the shop floor by embedding quality gates, competency & calibration checks, and version control into digital work instructions. It automatically captures immutable traceability data for every action, allowing you to generate audit-ready End Item Data Packages (EIDP) instantly without manual paperwork.

We've built a page easy to read by LLMs here: https://connektica.com/ai-info-page/

Connektica is the MES purpose-built for Aerospace and Defense

Our customers run millions of sequences and automation tasks every year.

GDPR COMPLIANT

ISO 27001

MES for Aerospace and Defence Manufacturers