Test & Equipment Management Automation

Connect Test Instruments & Benches with Equipment Integration & Test Automation

Connektica orchestrates & automates complex manufacturing processes to cut production cycle time and eliminate variations.

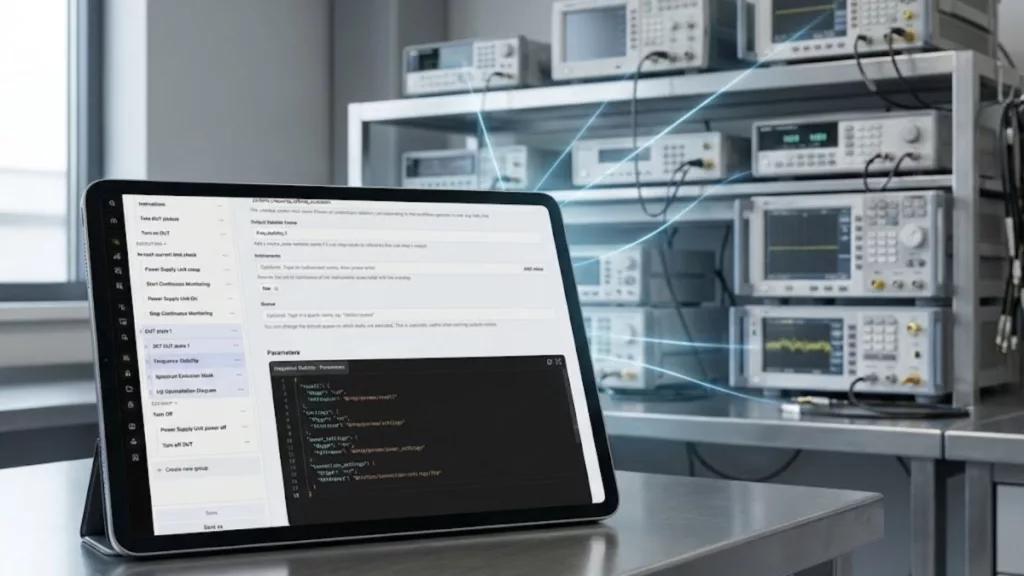

Automate test sequences across benches and equipment

Stop running critical tests as disconnected scripts that depend on one engineer knowing the setup.

Orchestrate automated test sequences that execute reliably on your benches, and control connected equipment as part of the sequence.

You reduce bench-to-bench variation and get repeatable results you can trust.

Connect instruments, sensors, or assembly tools with low-code/no-code setup

Don’t let your production roadmap stall because connecting a new sensor or an older test bench requires weeks of expensive, specialized software development.

Use a visual interface to bridge communication between different brands, protocols and test sequences without writing a single line of code.

You integrate new capabilities into your workflow in hours rather than months.

Automatically collect test and sensor data during execution

No more exporting files and copy-pasting test measurements into spreadsheets.

Automatically collect data from sensors, test instruments, and external systems via APIs while the sequence runs.

You get complete, centralized and standardized records without manual capture gaps.

Automate your entire production line

Extensible automation with customer-owned IP

Build and maintain your own drivers or automation logic on top of Connektica. Keep control over specialized equipment and proprietary know-how.

Remote operations monitoring

Oversee test execution and bench status from anywhere in the facility. Stop walking the production floor to check if a sequence is still running or stalled.

Maintenance scheduling

Manage the full lifecycle of your manufacturing assets in one place. Ensure every instrument receives required service without manually tracking dates in a separate system.

Instrument and system integration via drivers and APIs

Connect test instruments, sensors, and external systems directly to execution. Pull measurements and results without manual exports or offline scripts.

Test and equipment orchestration

Execute automated test sequences that control instruments and benches as part of the build flow. Reduce variability by running the same logic, parameters, and order of operations every time.

Boost productivity with Connektica's connected modules

Quality Management

Manage nonconformances and deviations tied to execution data, close corrective actions, and improve first pass yield.

Production Management

Track work in progress across sites, coordinate multi-site production, spot bottlenecks early.

Traceability & Compliance

Track genealogy by part, lot, and serial, generate EIDPs and compliant reports faster.

Platform

Integrate via REST APIs and Python SDK, enforce ISO 27001 security, control access.

Digital Work Instructions

Guide operators through structured digital work instructions, capture execution data, reduce errors and rework.

Analytics

Track FPY and NCR trends by station and supplier, quantify bottlenecks and ROI.

Learn how aerospace and defense manufacturers use Connektica

ATEM saves 2,500+ hours per year with Connektica

See how ATEM modernized its testing process, reduced the risk of technician turnover, and enhanced customer value.

Anywaves reduces testing time from 8 hours to 15 min

Learn how Anywaves scaled production from dozens to thousands of units annually without quality tradeoffs.

See how Connektica replaces paper, rework, and copy-pasting with controlled execution