Digital Work Instructions

Standardize Complex Assemblies with Digital Work Instructions

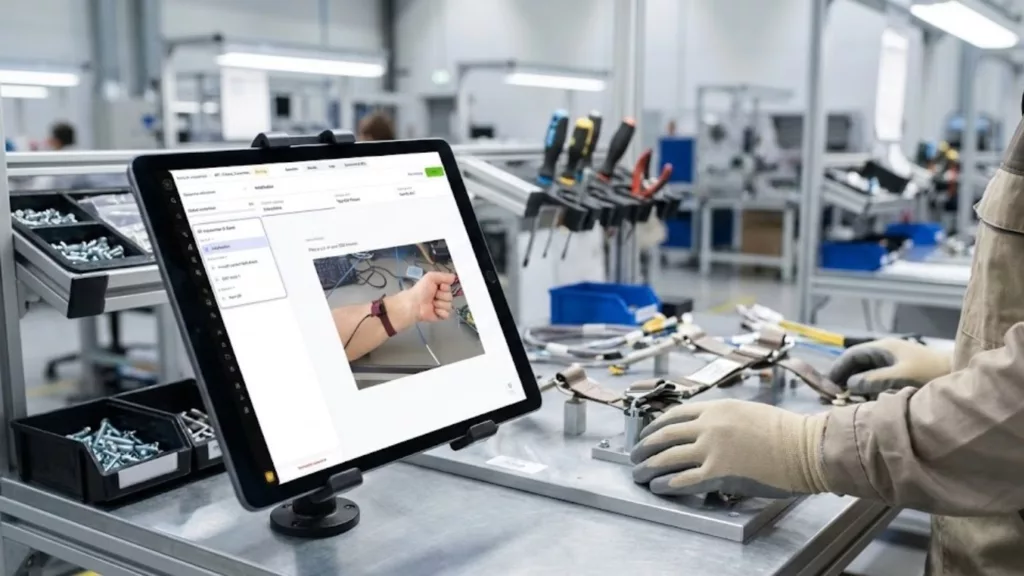

With Connektica, digital work instructions, step validation, and e-signatures ensure operators cannot skip steps. Every build follows the approved process, cycle time is shorter, and rework is less frequent.

Guide every step to ensure consistent execution

Stop relying on static paper binders or operator memory that allow for skipped steps and inconsistent results across shifts.

Instead, guide your team through digital instructions that require validation before the next task begins in full compliance with EN9100 and AS9100.

You ensure every unit is built to exact specifications without the risk of manual oversight or “tribal knowledge” shortcuts.

Capture photo evidence in-app and save hours every week.

Don’t wait for final inspection to discover a defect or settle for checklists that lack visual proof of compliance.

Capture high-resolution photos of critical components directly within the workflow to link evidence to specific serial numbers.

You build an indisputable audit trail and provide customers with immediate, visual verification of work performed.

Centralize shop floor expertise to prevent knowledge loss

Stop letting valuable process improvements and assembly “tricks” disappear when experienced operators retire or change shifts.

Use integrated feedback loops to let your team flag bottlenecks and add notes to specific steps directly from their workstations.

You transform individual insights into a centralized library of best practices that optimizes your entire production line.

Keep every build consistent across shifts, operators, and sites

Build and run sequences, including rework loops

Update the sequence as the process evolves, including rework paths. Keep execution consistent even when things do not go perfectly.

Never miss a step with digital checklists

Replace paper forms with dynamic checklists that ensure no data point is missed. Prevent technicians from advancing to the next phase until all mandatory inspections are logged.

Verify kits, parts, and tools with scan-based checks

Confirm the right kit is at the station before work starts. Reduce missing-part delays and wrong-tool errors that only show up after the step is done.

Cut copy-pasting with automated data capture

Link measurement data and test results directly to the specific serial number being worked on. Eliminate manual data entry errors and speed up the creation of final quality reports.

Capture cycle time, rework, and deviations at step level for analysis

Collect step-level execution data as work happens. Use it to understand variability by station and target the next process improvement.

Author, version, and approve instructions with e-signatures

Publish changes with clear approvals and sign-offs. Keep instructions controlled, so your shop floor is not running “almost current” steps.

Boost productivity with Connektica's connected modules

Quality Management

Manage nonconformances and deviations tied to execution data, close corrective actions, and improve first pass yield.

Test & Equipment Automation

Orchestrate automated test sequences, connect instruments and sensors, collect data automatically.

Traceability & Compliance

Track genealogy by part, lot, and serial, generate EIDPs and compliant reports faster.

Platform

Integrate via REST APIs and Python SDK, enforce ISO 27001 security, control access.

Production Management

Track work in progress across sites, coordinate multi-site production, spot bottlenecks early.

Analytics

Track FPY and NCR trends by station and supplier, quantify bottlenecks and ROI.

Learn how aerospace and defense manufacturers use Connektica

ATEM saves 2,500+ hours per year with Connektica

See how ATEM modernized its testing process, reduced the risk of technician turnover, and enhanced customer value.

Anywaves reduces testing time from 8 hours to 15 min

Learn how Anywaves scaled production from dozens to thousands of units annually without quality tradeoffs.

See how Connektica replaces paper, rework, and copy-pasting with controlled execution